InfraredHeaters.com Questions? 1-800-442-2581 |

Our secure online

ordering website: www.MorElectricHeating.com.

|

|

| Home | Products | Accessories | Ordering | Contact Us | Search | ||

InfraredHeaters.com Questions? 1-800-442-2581 |

Our secure online

ordering website: www.MorElectricHeating.com.

|

|

| Home | Products | Accessories | Ordering | Contact Us | Search | ||

Thermoforming of Plastics

Heaters Used in Thermoforming

Thermoforming Machine Manufacturers

The Thermoforming Division of the Society of Plastics Engineers.

Thermoforming is the heating and molding of plastic sheet or film of a variety of thickness and sizes into products. The types of electrical infrared heaters used in thermoforming are: ceramic, quartz tubes and lamps, quartz emitters, metal sheathed tubular (CalrodŽ)*, open coil wire elements, flat faced panel (quartz fabric and glass panels) and convection heater type ovens. Gas heaters are also used and recently a catalytic (no flame) gas heater was developed. Sheets 14 feet long and thickness of 1/4" or greater are formed on the largest machines. The plastic sheet is heated to the desired softness or "sag" and then formed in a mold with a vacuum underneath or pressure from above. Thermoforming is said to be somewhat of a "black magic" because great skill is needed to create perfect parts. Molds can be made from metal, ceramic and wood. Thermoforming machines are used in conjunction with routers, trimming equipment and other finishing equipment to create plastic products. The types of thermoformers that are in use today fall in the category of rollfed (webfed) or sheetfed. Vacuum forming machines (a vacuum pulls the plastic sheet into the shape of the mold below,) pressure forming machines (air pressure from above presses the plastic sheet into the shape of the mold) and matched male/female molds are available.

Rotary or Shuttle (Sheetfed machines with one to four stations the plastic

moves through to load, heat, mold and unload.)

Twin Sheet (Two sheets are pressed together with two female molds to create

products with hollow structures such as plastic pallets and bubble wrap.)

Inline (Plastic is fed off of a roll to continuously mold products such as

clam shell packaging.)

Cut Sheet / Sheet Fed (Single sheets are fed in by hand.)

Table Top (Small machines using sheets or rolls useful for small runs of

small products or for prototyping.)

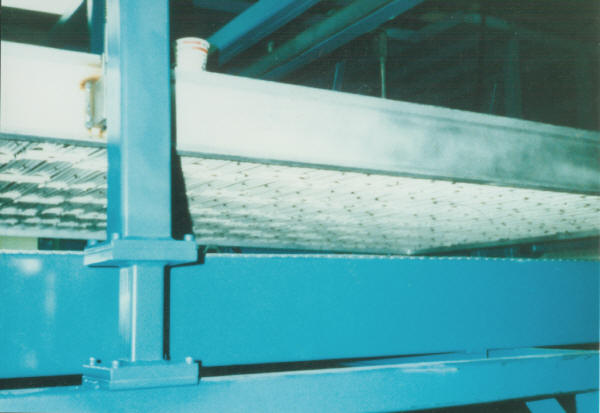

The top heating panel of a large thermoforming machine with hundreds of ceramic heaters.

The increased usage of thermoformed plastic products in our society, the advancing technology of thermoforming, an increase in high performance products and the precise heating required for some applications has brought a resurgence of interest in Ceramic Infrared Heating Elements. Along with Quartz and Metal Sheathed (CalrodŽ)* they are one of the most popular heaters used. Their gentle heating nature, high efficiency level, and ease of control make them the ideal thermoforming heat source. They are also one of the most zoneable thermoforming heaters available because of their small size.

* Calrod is a registered tradename of the General Electric Company.

|

We are a distributor of infrared heaters. Always consult manufacturers installation instructions for proper installation of the products or systems shown on this website. © Copyright 1999-2019 Mor Electric Heating Assoc., Inc. MOR

ELECTRIC HEATING ASSOC., INC. |