InfraredHeaters.com Questions? 1-800-442-2581 |

Our secure online

ordering website: www.MorElectricHeating.com.

|

|

| Home | Products | Accessories | Ordering | Contact Us | Search | ||

InfraredHeaters.com Questions? 1-800-442-2581 |

Our secure online

ordering website: www.MorElectricHeating.com.

|

|

| Home | Products | Accessories | Ordering | Contact Us | Search | ||

Chromalox® CPHI Series Flat-Faced Wide Area Radiant Panel Heaters

![]() Secure Credit Card ordering online

Secure Credit Card ordering online

Chromalox

CP Series Wide Area Radiant Heaters

Solar Products Panel Heaters

Black Body Panel Heaters

We are an authorized Chromalox®

distributor.

Specifications:

Applications:

|

|

Moisture Removal from Bottles, Cans and Components |

|

|

Drying Automobile Underseal, Adhesives, Lacquer, Printing Ink, Plastic Granules, Pharmaceuticals and Pottery to "biscuit" state |

|

|

Nylon and Dye Heat Setting |

|

|

Firing Vitreous Enamels |

|

|

Soften Plastics prior to Thermoforming |

|

|

Soldering and Brazing (i.e., reflow soldering on printed circuit boards) |

|

|

Heating for Shrink Fitting |

|

|

Sealing Glass to Metal |

|

|

Shrink and Blister Packaging |

|

|

Curing and Baking of PTFE coatings, mirror backings, PVC foil prior to lamination, resin coatings on paper, metal textiles and wood, paint finishes including powder coatings and enamel, shoe adhesives and fillings, latex backing for carpet |

|

|

Brown Food prior to Freezing |

|

|

Wherever Close Maximum Heat is Required, such as Process Boosting |

Features

Highest Watt Density Available (5.76 kW/Ft 2 ) of any Medium Wave Infrared Radiant Panel

Heater, due to thermal and electrical properties of the grooved quartz face plate.

Uniform Radiation Pattern Assured with a wide flat infrared surface versus the line

pattern given in normal radiant heaters. This eliminates uneven heating of the work and

allows uniform heating of a stationary surface such as in an indexing process.

Lower Operating Cost with up to 80% of the input energy transmitted to and absorbed by the

work material. The maximum amount of radiant energy is transferred to the work with very

low heater convection losses. Typical installation distance of two to four inches from the

work surface significantly reduces the energy input.

External Reflectors Not Required — The refractory board and bulk insulation behind

the heating element help prevent back heat loss. This eliminates the need for external

reflectors.

Costly Downtime Minimized — There is no deterioration of the output radiation level

with heater life and no reflectors to clean which could cause downtime and increased

maintenance costs. The unit is resistant to vibration because of the compact homogeneous

construction.

Easy Installation — The light weight building block approach allows for a modular

installation which is easily expandable.

Note — CPHI heaters mount only so that the coil direction is in the horizontal plane.

Repeatable Process Performance Assured — Used with closed loop control, the system

automatically compensates for ambient temperature ranges and line voltage fluctuations.

Maximum energy transfer requires matching the peak wavelength output to the specific

material absorption characteristics. Because the peak wavelengths of the flat surface

heater are repeatable

and adjustable, the quality output of the process is assured.

CPHI heaters produce micron levels between 2.5 and 6.0. At these micron levels the

majority of the CPHI heaters fall into the middle of the IR spectrum, categorizing them as

medium wave heaters.

Single heating elements or multiple elements can be zoned and wired to achieve specific

heating profiles.

Outer edges of the element can have gradual increasing watt density to compensate for

increasing watt density to compensate for production edge losses.

Easy to Control — The use of time proportioning control with closed loop feedback,

such as Chromalox 2104

temperature controllers or SCR power controllers

assure easy and dependable system control. Thermowells may be

offered in two locations in the heater interior. Suitable to accept Chromalox standard

thermocouples, they sense emitter temperature ensuring accurate wavelength emission.

Fast response time of the unit reduces thermal lag.

Overtemperature Control — It is strongly recommended that these units be

controlled such that overheating and premature

failure do not occur. This is of particular importance in oven usage, where high ambient

temperatures exist.

CAUTION — Hazard of Fire. These radiant heaters must not be operated in the presence

of flammable vapors, gases or

combustible materials without proper ventilation and/or other safety precautions in

compliance with either the National Fire

Protection Bulletin 86A entitled "Ovens and Furnaces" or the authority having

jurisdiction.

Construction

1. Heating Element — Precision iron base resistance wire, designed to give extended

life and uniform emission over

entire radiating surface.

2. Emission Surface — Grooved fused quartz face plate for CPHI type heaters. Special

ratings with aluminum emission surfaces are available for applications such as in the food

industry.

3. Frame — Heavy gauge, heat-resistant aluminized steel.

4. Heating Element Support — Fibrous 4. Heating Element Support — Fibrous

ceramic material specially developed for

high insulation qualities, durability, shock resistance, asbestos free.

5. Insulation — High temperature insulation to minimize heat loss from back of

heater.

6. Terminals — Stainless Steel terminals in a 4 x 4" junction box are provided

with CPHI type heaters.

7. Thermowell — Quality tubular quartz thermowell, with strain relief, to accept a

Chromalox C-700JU or C-700KU

thermocouple on units with suffix T

in model number. Standard placement of thermowell is on side of heater. Specials are

available with thermowell exiting back of heater.

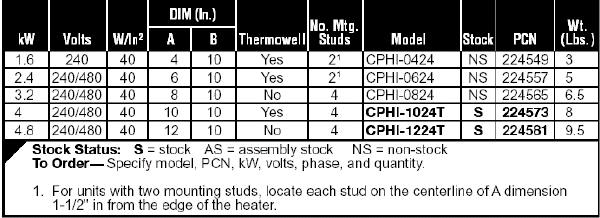

Dimensions (Inches)

Specifications and Ordering Information:

|

Secure online Credit Card ordering - SSL encryption. delivery time: typically ships in 5-7 workdays or less plus allow additional time for your selected UPS or FedEx shipping method. Price below does not include shipping cost which is calculated using your address before entering your credit card number. |

||

| Model# | Description |

Click "Select" below to see our price and our actual real-time quantity in stock |

| CHROM224573 | CPHI-1024T 240/480V1P 4.0KW | |

| The following heaters are Non Stock, delivery time: typically ships in 25-27 workdays or less plus allow additional time for your selected UPS or FedEx shipping method. | ||

| CHROM224549 | CPHI-0424 240/480V1P 1.6KW | |

| CHROM224557 | CPHI-0624 240/480V1P 2.4KW | |

| CHROM224565 | CPHI-0824 240/480V1P 3.2KW | |

| CHROM224581 | CPHI-1224T 240/480V1P 4.8KW | |

| (You must have the free Adobe Acrobat Reader plug-in.) |

|

Other Chromalox®

products are available upon request. Please fill out

our contact form.

Chromalox®

is a registered trademark.

|

We are a distributor of infrared heaters. Always consult manufacturers installation instructions for proper installation of the products or systems shown on this website. © Copyright 1999-2019 Mor Electric Heating Assoc., Inc. MOR

ELECTRIC HEATING ASSOC., INC. |